Certification (reporting on request)

-Cradle2Cradle Institute, achieved result Cradle2Cradle Bronze

-MRPI, ISO 14025 Environmental Product Declaration compliant

-MRPI, LCA in accordance with SBK determination method, MKI A-D 0.24ct/m2 for the variant applied in the mass

-Efectis, 1350-1:2018, B-s1.d0 with the addition of the new borate-free option B-s2.d0 (ask for this specifically)

-Frauenhofer, DIN EN 16516, VOC, complies with VOC and SVOC Building Products 2015/LCI list 2015

-Intertek standard ASTM D7234, bond strength >736 to <12600 its own weight

-Intertek, ASTM C1338-19 Standard, Microbiological Performance, Compliant

-Intertek, standard ISO 105-A02, color change, class 5

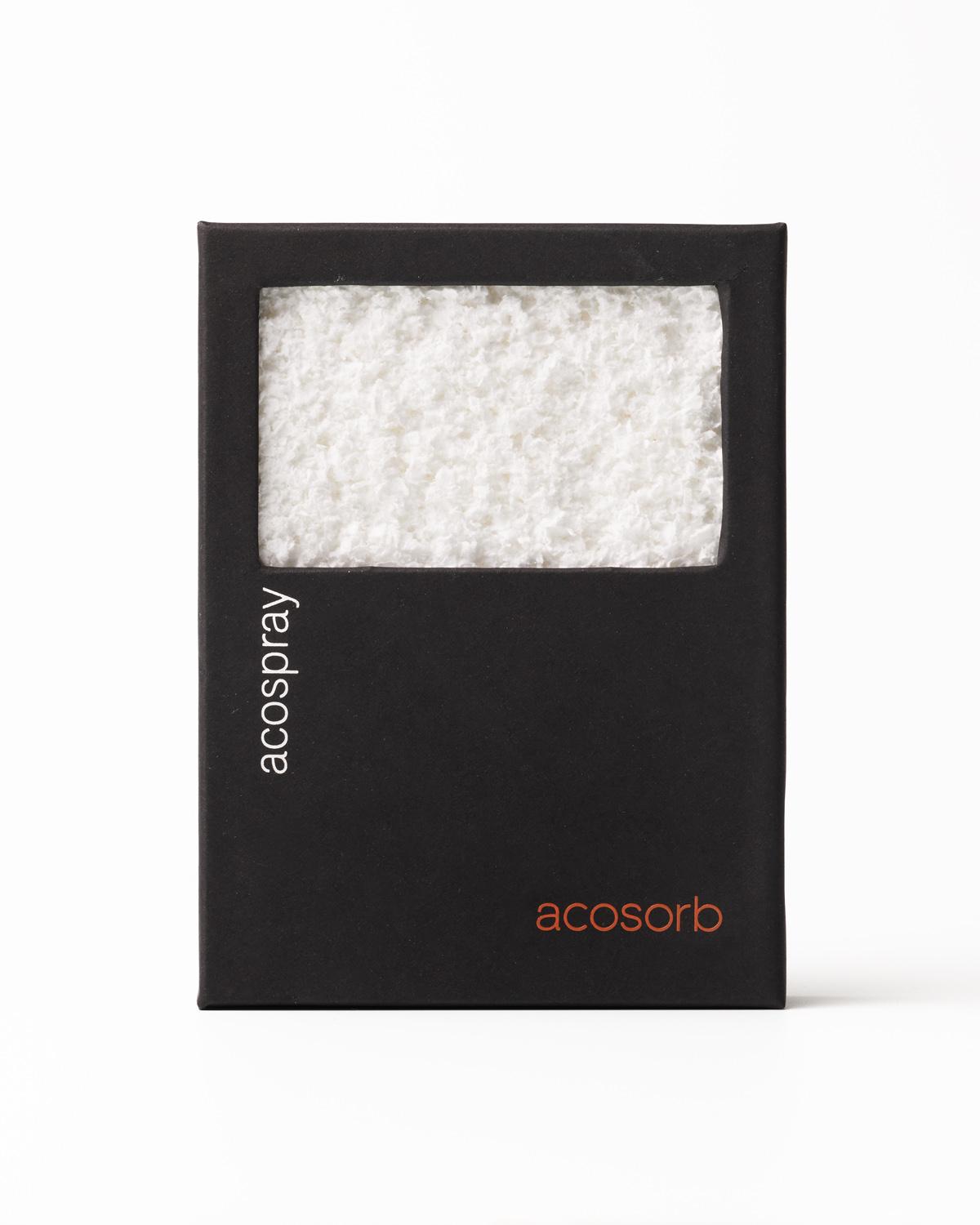

Colours

White and any other specific color by adding pigment to the adhesive.

Cleaning

Option 1: Any dust and cobwebs can be removed using a vacuum cleaner with a soft brush attachment.

Option 2: Treat the surface with dry ice. A maintenance contract can also be concluded for this.

Repairs

Repairs can be carried out easily with our mini machine (38kg).

Painting

The material can be oversprayed using an airless spraying technique. We do not recommend using a rolling technique.

Remove acoustic layer

Moisten the material and let it soak for 24 hours. After that it is easy to remove.

Application Basics

-Substrate must be clean, dry and airtight (close plasterboard seams)

-We recommend applying a green plasterboard as a substrate

-The flatness of the surface determines the flatness of the end result

-Acoprimer promotes adhesion and ensures a proportional suction power of the substrate

-Extend junction boxes, etc., to the thickness of the spraying work

-If not ended by a wall or frame, a sealing profile must be installed

-Pre-treat metal parts against rusting

-Installation using mobile scaffolding and/or scissor lifts

-Temperature during and after application >15°C

-View our standard detail set for more information, call our specialists on +31 (0)20 7173000 or send an email to: info@acosorb.nl